Industrial Lifting Simplified: The 2026 Guide to Choosing Electric Hoists

In the modern industrial landscape, the difference between a seamless production line and a bottleneck often comes down to the reliability of your lifting equipment. Electric hoists have evolved from simple mechanical aids into sophisticated, data-driven components essential for warehouses, steel mills, and shipyards.

As we navigate 2026, procurement is no longer just about “how much can it lift?” It is about how that lifting capacity integrates into a broader, smarter ecosystem. This guide cuts through the marketing noise to provide engineers and plant managers with a technically grounded roadmap for selecting electric hoists in the current industrial climate.

The Core of Modern Material Handling

At its simplest, an electric hoist is a powered device that manages loads using an electric motor, a braking system, and either a wire rope or a chain. However, their true value lies in their integration. In 2026, these units act as the “beating heart” of larger systems, such as overhead cranes, jib cranes, and the versatile 【Gantry Crane】.

Choosing the right hoist directly impacts four critical operational areas:

- Personnel Safety: Reducing manual handling risks and equipment failure.

- Throughput: Minimizing the time taken for each lift-and-place cycle.

- Asset Protection: Precision control prevents damage to high-value loads.

- Regulatory Compliance: Meeting increasingly stringent international safety codes.

Technical Segregation: Wire Rope vs. Chain Hoists

The first decision in any procurement process is selecting the lifting medium. While the gap is closing due to material science, the applications remain distinct.

1. Wire Rope Electric Hoists

Preferred for medium to heavy-duty industrial environments. They offer smoother travel and are the standard choice for high-capacity lifting.

- Best for: Steel processing, power plants, and large-scale 【Gantry Crane】 systems in outdoor yards.

- 2026 Edge: New galvanized high-tensile ropes provide better corrosion resistance without sacrificing flexibility.

2. Electric Chain Hoists

Compact and often more economical, these are the workhorses of assembly lines and smaller workshops.

- Best for: Precision positioning in maintenance stations or light overhead systems.

- 2026 Edge: Modular designs now allow for “plug-and-play” chain replacements, drastically reducing downtime.

The 2026 Selection Matrix: Beyond the Weight Limit

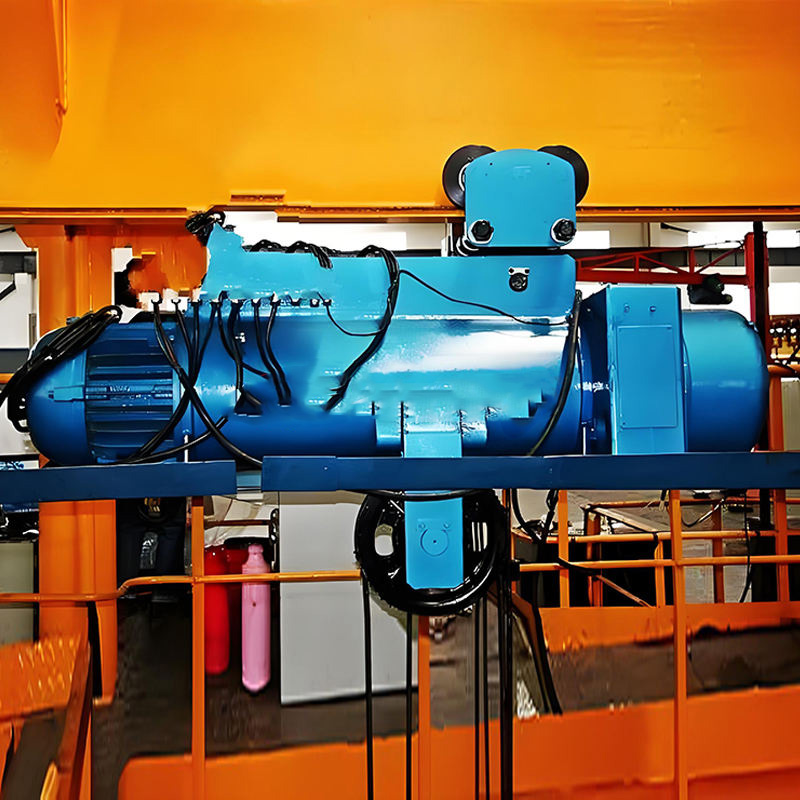

Weiyuan CD/MD Electric Hoist

The Weiyuan CD/MD Electric Hoist is a universal steel wire rope hoist designed for durability, reliability and broad industrial applications. Available in single-speed (CD) and dual-speed (MD) versions, it is suitable for workshops, warehouses and assembly lines, and can be mounted on overhead equipment including single beam cranes and gantry cranes for efficient material handling. :contentReference View Product / Get Quote

Standard procurement often fails because it focuses on static load capacity while ignoring dynamic operational reality.

Duty Class: The Silent Performance Killer

One of the most frequent mistakes is underestimating the Duty Class (ISO/FEM standards). An M3 rated hoist might lift 10 tons once an hour, but if you ask it to do so every five minutes, the motor will overheat. For regular industrial use, M4 or M5 is the baseline. For continuous operations or harsh environments, M6+ is mandatory.

Integration with Mobile Systems

If you are mounting a hoist on a 【Gantry Crane】, the requirements change. Unlike fixed overhead cranes, a 【Gantry Crane】 often operates outdoors and moves across uneven surfaces. The hoist must be engineered to handle:

- Lateral Forces: Increased stability to counter movement during travel.

- Environmental Exposure: IP65 or higher protection ratings against dust and moisture.

- Dynamic Loading: Compensation for wind loads in outdoor shipyard or construction applications.

Safety Features: The Non-Negotiables

In 2026, safety is built into the logic of the machine. When reviewing specifications, ensure the following features are not “optional extras” but integrated standards:

- Dual Braking Systems: Combining mechanical and electromagnetic brakes for redundant safety.

- Variable Frequency Drives (VFD): Standardizes “soft starts” and “soft stops,” which prevents the load from swinging—a critical factor when using a 【Gantry Crane】 in tight spaces.

- Real-time Diagnostics: IoT modules that track motor temperature and brake wear, allowing for predictive maintenance rather than reactive repairs.

Lifecycle and Maintenance Strategy

A high-quality hoist is a 15-to-20-year asset. To ensure this lifespan, look for Modular Construction. This allows your team to replace a specific contactor or a single gear stage without dismantling the entire unit.

Furthermore, verify the availability of local wear parts. A “bargain” hoist from an overseas supplier becomes a liability if a simple limit switch takes three weeks to clear customs.

FAQ: Professional Insights

Q: Can I use a standard indoor hoist on an outdoor Gantry Crane? A: It is not recommended. Outdoor 【Gantry Crane】 applications require hoists with specialized weather protection, including stainless steel hardware, anti-corrosive paint, and motor covers to prevent water ingress.

Q: How does VFD (Variable Frequency Drive) improve my ROI? A: VFD reduces the mechanical shock on the gears and motor. This extends the lifespan of the equipment by up to 30% and reduces energy consumption by optimizing power draw during the start-up phase.

Q: What is the most common cause of hoist failure? A: Overheating due to incorrect duty cycle selection and “jogging” (repeatedly pressing the button for tiny movements). Modern hoists with thermal protection and VFD control largely mitigate these issues.

Q: Is there a significant difference between CE and FEM certifications? A: CE is a broad safety directive for the European market, while FEM (Federation Européenne de la Manutention) specifically addresses the design and duty life of the lifting mechanism. For industrial reliability, FEM/ISO ratings are more technically descriptive.