Cranes

Precision-Engineered Electric Hoists: Ensuring Operational Safety and Durability

In heavy industrial environments, precision is not a slogan—it is a prerequisite for safety. As lifting operations grow more demanding in 2026, electric hoists are expected to deliver not only lifting force, but predictable behavior, structural stability, and long-term reliability. For facility managers and safety officers, the question is no longer whether an electric hoist can lift a load, but whether it can do so consistently, controllably, and safely over years of operation.

This article examines how precision-engineered electric hoists are reshaping industrial lifting by focusing on mechanical accuracy, integrated safety systems, and durability under real-world conditions.

Precision Engineering as a Design Discipline

A precision-engineered electric hoist differs from a conventional model at a fundamental level. The difference is not cosmetic—it lies in tolerances, materials, and how forces are managed internally.

High-Accuracy Gear Trains

In lower-grade hoists, cast gears with loose tolerances often introduce vibration, noise, and uneven wear. Precision-engineered hoists instead use hardened alloy steel gears that are machined and ground to tight tolerances. The result is smoother torque transmission, reduced frictional heat, and significantly longer gearbox life.

This level of mechanical accuracy becomes especially important in applications where lifting cycles are frequent and loads are close to rated capacity.

Braking Systems Designed for Predictability

Precision engineering also defines how a hoist stops—not just how it lifts. Modern electromagnetic braking systems are designed to engage instantly and automatically in the event of power loss. This fail-safe behavior is essential in complex lifting setups, particularly when hoists are installed on mobile structures such as a Gantry Crane, where inertia and environmental forces increase risk.

A predictable braking response protects both the load and the surrounding infrastructure.

Safety Built Into the Structure, Not Added Later

In 2026, operational safety is increasingly driven by preventive intelligence rather than reactive measures. Precision-engineered hoists integrate safety mechanisms directly into their control architecture.

Intelligent Load Management

Mechanical overload devices are gradually being replaced by electronic load monitoring systems. These systems continuously measure actual lifting force and communicate directly with the motor controller. When an overload condition is detected, the hoist responds in a controlled manner—often allowing safe lowering while recording the event for inspection and compliance tracking.

This approach reduces sudden stoppages and provides valuable operational data.

Dual-Stage Limit Protection

Precision hoists typically use redundant limit switch systems. The first stage reduces speed as the hook approaches travel limits, while the second stage cuts power entirely. This staged response minimizes impact forces and prevents damage to drums, wire ropes, and load chains over time.

Such protection is especially valuable in high-lift applications where stopping distance matters.

Durability Under Real Industrial Conditions

Durability is not defined by specifications alone—it is proven by performance in harsh environments. Precision-engineered hoists are designed with this reality in mind.

Environmental Sealing and Protection

Industrial-grade hoists increasingly feature IP55 or higher protection ratings, safeguarding motors and electronics from dust ingress and water exposure. For outdoor operations, especially those involving a Gantry Crane, sealed enclosures and corrosion-resistant finishes are essential to maintaining long-term reliability.

Structural Stability During Travel

When a hoist is mounted on a moving structure, durability also depends on how well it tolerates vibration and dynamic loading. Precision mounting interfaces and reinforced housings help prevent loosening and misalignment during long travel motions, a common challenge in yard and shipyard operations.

Control Systems That Enhance Both Safety and Efficiency

Precision engineering extends beyond mechanical components into control logic and operator interaction.

Variable Frequency Drives and Motion Stability

Variable Frequency Drives (VFDs) allow precise control over acceleration and deceleration, reducing shock loads and load swing. In modern systems, this controlled motion significantly improves operator confidence and positioning accuracy.

In outdoor lifting scenarios—where wind and load surface area amplify movement—VFD control is a key contributor to safe operation.

Operator-Centered Interfaces

User experience has become a safety factor in its own right. Precision-engineered hoists now feature clearer pendant layouts, responsive controls, and real-time feedback such as load weight and operating status. Clear information reduces operator error and shortens reaction time during critical lifts.

Maintenance as Part of the Design Philosophy

Durability is sustained through serviceability. Precision hoists are designed to be maintained efficiently rather than replaced prematurely.

Modular Access and Wear Indicators

Key components such as brakes, contactors, and control panels are accessible without full disassembly. Visual wear indicators on consumable parts simplify inspections and reduce the likelihood of overlooked degradation.

Operational Data for Smarter Decisions

Many modern hoists record operating hours, overload events, and emergency stops. This data allows managers to identify patterns, adjust training, and plan maintenance proactively—turning the hoist into a source of operational insight rather than a hidden risk.

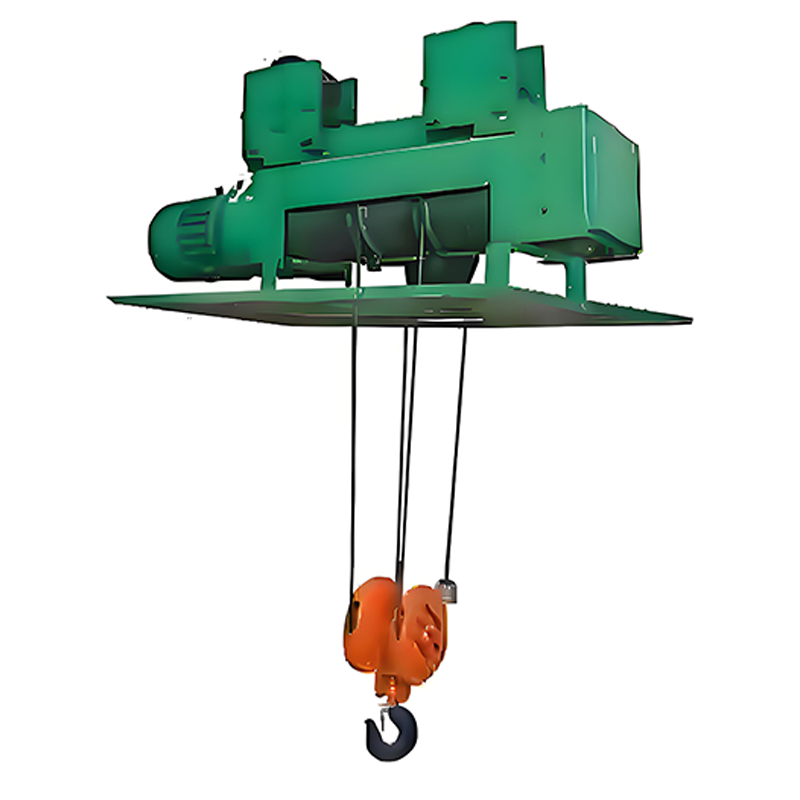

Weiyuan CD/MD Electric Hoist

The Weiyuan CD/MD Electric Hoist is a universal steel wire rope hoist designed for durability, reliability and broad industrial applications. Available in single-speed (CD) and dual-speed (MD) versions, it is suitable for workshops, warehouses and assembly lines, and can be mounted on overhead equipment including single beam cranes and gantry cranes for efficient material handling. :contentReference View Product / Get Quote

The Hidden Cost of Low-Precision Equipment

While lower-cost hoists may appear attractive during procurement, the long-term financial impact often tells a different story.

Common consequences include:

- Increased unplanned downtime

- Faster wear of gears and braking components

- Higher spare part consumption

- Greater safety exposure and liability

In contrast, precision-engineered hoists typically deliver lower total cost of ownership, especially in facilities with continuous or safety-critical lifting operations.

Whether installed on a fixed overhead system or integrated into a heavy-duty Gantry Crane, precision pays dividends through reliability and peace of mind.

Frequently Asked Questions (FAQ)

Q1: What distinguishes a precision-engineered electric hoist from a standard model?

A precision-engineered hoist uses tighter manufacturing tolerances, higher-grade materials, and integrated control systems to deliver smoother motion, improved safety, and longer service life.

Q2: Why is environmental resistance so important for hoist durability?

Dust, moisture, and corrosive elements accelerate wear on motors and electronics. High IP ratings and protective coatings are essential for maintaining reliability in harsh conditions.

Q3: Does precision engineering reduce maintenance requirements?

It does not eliminate maintenance, but it makes it more predictable and efficient by reducing abnormal wear and simplifying inspection processes.

Q4: Are precision-engineered hoists only necessary for heavy-duty applications?

They provide the greatest value in high-duty or safety-critical environments, but even moderate-use facilities benefit from improved control and reduced downtime.