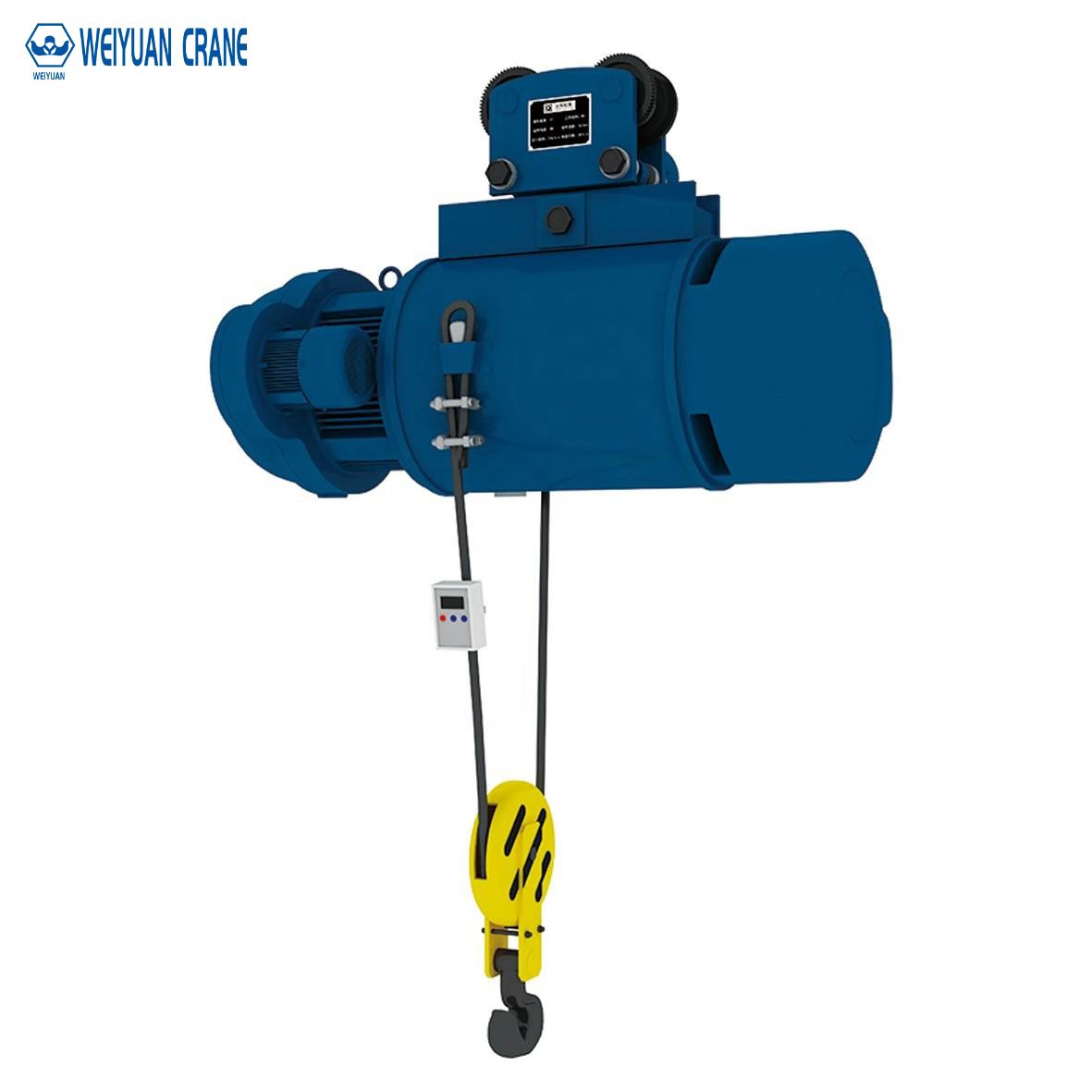

Roap hoist

Roap Hoist

Weiyuan chain hoists – high productivity, efficiency, safety and reliability Weiyuan chain hoists meet all the requirements of state-of-the-art hoist units, such as high productivity, efficiency, safety and reliability, and give you the certainty of a secure long-term investment. We develop and produce materials handling solutions for all industries and companies of all sizes, from small workshops to major industrial corporations.Product overview

The D3 series workstation intelligent machine adopts an aluminum shell, which is lightweight and sturdy, and has unique patented technology. It uses an industrial processor controlled servo drive system to achieve unparalleled improvement in handling speed and assembly accuracy. It combines advanced technology with human motion commands, like an extended arm of an operator, making it easy to lift and move heavy objects. The intelligent lifting machine at the Golden Axis workstation maximizes production efficiency, reduces the physical exertion of production personnel, lowers product damage rates, and minimizes the occurrence of work-related accidents.Product Features

01 Handle/Floating Dual Mode )Handle mode: ergonomically designed, the load can be moved up and down with one person and one hand, ensuring correct control. )Floating mode: fingertip control, move quickly and slowly according to the operator’s wishes, effortlessly responding instantly. Operators can also directly manipulate the load with both hands to achieve precise positioning. 02 Continuously variable transmission/controllable speed The workstation intelligent hoist can move quickly or slowly according to the operator’s actions, and can move according to their preferences. Especially suitable for assembly applications that require both fast movement and slow, precise alignment 03 Precise Alignment Function) The extremely precise alignment control function allows operators to accurately and stably manipulate delicate and fragile work items. 04 Safe and Reliable )Overload protection function: Automatic weight sensing can sense the weight of the load. If the rated load is exceeded, an alarm will be immediately triggered and the load will not be allowed to be lifted. Photoelectric sensing function: The operating handle of the workstation intelligent hoist is integrated with a photoelectric sensor, which only allows the device to move after sensing that the operator is in place to prevent accidental contact. Anti rebound function: Prevent potential safety hazards such as movement and rebound when the weight of the load mounted on the intelligent hoist at the excavator consultation station suddenly changes. Mountain power outage protection function: When a power outage occurs, the safety brake of the intelligent lifting device actively locks, preventing the load from falling 1. Soft limit function: The system has a soft limit function to reduce the risk of impact and flexibly limit the range of workpiece movement.Application scenarios

Our rope hoists have been utilized by diverse industries to lift heavy loads, with some key sectors including: 1.Aerospace 2.Steel coil handling and warehousing 3.Gas turbine/turbine production 4.Precast concrete 5.Paper converting 6.Manufacturing production 7.Plastic injection molding 8.Automotive 9.GalvanizingWhat are the main components of a rope hoist?

Main Components of a Rope Hoist

- Drum: A cylinder where the rope winds.

- Motor: Powers the drum to rotate.

- Brake: Stops the load from falling during power failure.

- Load Hook: Attaches and moves the load.

Contact Weiyuan Today for More Information on Our Rope Hoists

In need of reliable rope hoists from industry experts?Reach out to our team today!

We are always up to something new! Check out our case studies to see how our solutions have helped our clients achieve their goals.