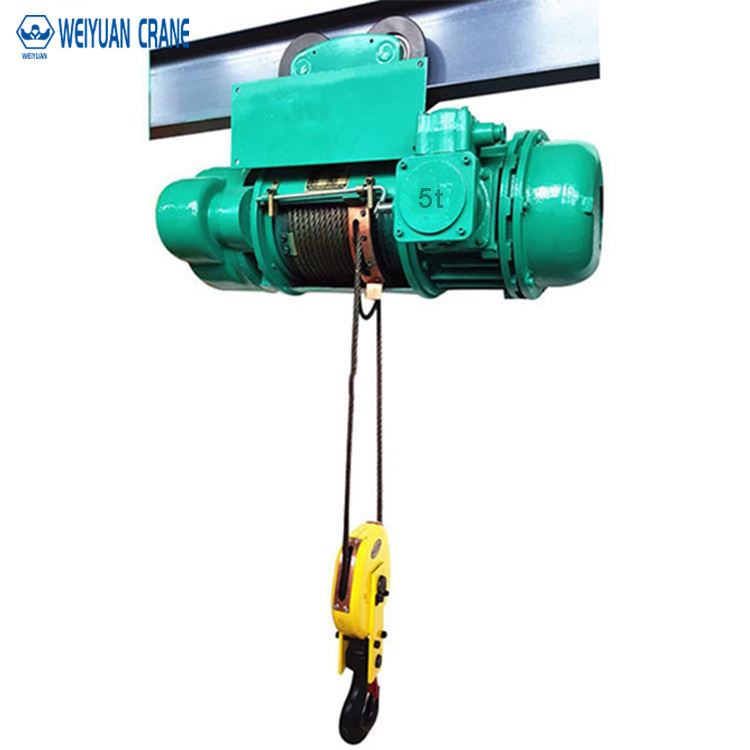

Universal electric hoist

Electric Hoist for Galvanizing

Product Overview

The Electric Hoist for Galvanizing by Weiyuan is a specialized lifting product developed to meet the complex process requirements and harsh working environments of the galvanizing industry. Engineered for high efficiency and intelligent automation, this hoist features a lightweight, modular, and parametric design. It offers superior performance, advanced technology, and robust safety and reliability. Controlled by an advanced variable frequency speed regulation system, this hoist is the core component for creating a safe, energy-saving, and highly productive material handling system in any modern galvanizing workshop.

Product Advantages

High-Efficiency Performance

Designed specifically for the hot-dip galvanizing process, this hoist features fast lifting and running speeds. With a work level rated up to M7, it is built for high-frequency, demanding cycles to maximize plant throughput and operational efficiency.

Precision Automation and Control

The application of automatic control technology and an advanced variable frequency drive (VFD) enables highly accurate positioning. This ensures the stability of the galvanizing process and the proper, repeatable transfer of materials between dipping tanks.

Built for Harsh Environments

Every component is selected and designed to withstand the corrosive, high-humidity, and high-temperature environment of a galvanizing plant. This specialized construction ensures durability, reliability, and a long service life.

Customizable for Any Workflow

This hoist can be integrated into a variety of crane systems to perfectly match the logistics of your workshop. It is suitable for use on single-beam cranes, suspension cranes, or complex systems with transferable and cross-track capabilities.

Energy-Saving and Lightweight Design

The hoist’s lightweight and modular design reduces the overall weight of the crane system, leading to lower structural loads on the building and reduced energy consumption during operation, promoting an environmentally friendly workflow.

Advanced Safety and Intelligent Functions

Equipped with a full suite of intelligent features, including electric anti-sway, inching movement for precise approaches, zero-speed hover to prevent hook slip, and regional load limits for enhanced safety.

Application Scenarios

Primary Hoist on Galvanizing Cranes

The core application is as the main lifting mechanism on single-beam, double-beam, or suspension cranes used in hot-dip galvanizing lines for dipping steel components into treatment tanks.

Pickling and Pre-Treatment Lines

Ideal for the pre-treatment stages of galvanizing, such as pickling and fluxing, where its corrosion resistance and precise control are essential for handling materials in acidic environments.

Modernizing Existing Crane Systems

An excellent choice for upgrading older galvanizing cranes. Replacing an outdated hoist with this modern, VFD-controlled unit can significantly improve a line’s safety, efficiency, and level of automation.

Plating and Chemical Treatment Facilities

Suitable for any surface treatment or plating operation that requires a robust, corrosion-resistant hoist capable of precise, repeatable movements in a harsh chemical environment.

Product Specifications and Dimensions

| Specification | Parameters |

|---|---|

| Product Name | Electric Hoist for Galvanizing |

| Lifting Capacity | 3t – 10t |

| Lifting Height | 6m – 18m |

| Work Level Classification | M5 – M7 |

| Lifting Speed | 1.35 m/min – 13.5 m/min |

| Running Speed | 3 m/min – 40 m/min |

| Control System | Variable frequency speed regulation |

| Key Feature | High-duty, corrosion-resistant design |

Features at a Glance

✓ High-Duty Performance: Work level up to M7 for continuous, high-speed operation.

✓ Corrosion-Resistant: Engineered to withstand the harsh environment of galvanizing.

✓ Automated Precision: Ensures accurate positioning for stable process control.

✓ Advanced VFD Control: Provides smooth, safe, and precise handling.

✓ Lightweight and Modular: Energy-saving and easy to integrate.

✓ Electric Anti-Sway: Guarantees stable load transport between tanks.

✓ Wireless Expansion Ready: Connects to the Weiyuan Crane Industrial Internet Platform.

FAQ

Q: Why do I need a special hoist for galvanizing?

A: Standard hoists are not designed to withstand the corrosive fumes, high humidity, and high temperatures of a galvanizing plant. A specialized hoist uses corrosion-resistant materials, sealed components, and robust construction to ensure safety, reliability, and a long service life in this harsh environment.

Q: Can this hoist be automated?

A: Yes. With its advanced automatic control technology and optional wireless expansion, the hoist can be fully integrated into an automated production line, receiving commands from a central control system to perform its tasks without manual intervention.

Q: What is the benefit of the M7 work level?

A: An M7 work level is a high-duty classification, meaning the hoist is designed for a very high number of operating cycles and near-continuous use. This is essential in a production-focused environment like a galvanizing plant where the hoist is constantly working.

Q: How does the Variable Frequency Drive (VFD) help?

A: The VFD allows for smooth acceleration and deceleration, which minimizes load swing (sway). It also enables multiple speed settings, including very slow speeds for precise positioning when lowering parts into tanks, which improves both safety and process quality.

Q: Can this hoist be fitted to my existing crane?

A: Yes, this hoist is designed with a modular structure and can be adapted to fit most existing single-beam or suspension crane systems, making it an excellent upgrade for improving the performance and safety of an older galvanizing line.