Low-Maintenance Bridge Crane Systems: Reducing Downtime with Advanced VFD Control

In the relentless rhythm of industrial manufacturing, downtime is the enemy. Every minute a crane sits idle due to a burnt-out motor or a snapped coupling, production targets slip further away, and costs mount. For facility managers and procurement specialists, the goal is simple but elusive: achieve maximum uptime with minimum maintenance intervention.

While traditional contactor-based control systems have been the industry standard for decades, they are increasingly becoming a liability in modern, high-speed production environments. The mechanical shock of “across-the-line” starting wears down gears, brakes, and structures at an accelerated rate.

The solution lies in the intelligent application of Variable Frequency Drive (VFD) technology. By transitioning to VFD-controlled bridge crane systems, facilities can fundamentally alter the maintenance equation, transforming their overhead lifting assets from high-maintenance hardware into reliable, precision instruments.

This guide explores the engineering mechanics behind VFDs, their impact on Total Cost of Ownership (TCO), and why they are the cornerstone of low-maintenance lifting strategies.

The High Cost of “Bang-Bang” Control

To understand the value of VFDs, we must first look at the limitations of traditional systems. Standard overhead cranes often use single or two-speed contactor controls. When an operator presses the button, full voltage is applied to the motor almost instantly.

This results in high in-rush currents (often 600% of the full-load amps) and immediate, jarring torque. In the industry, we call this “bang-bang” control. The crane jerks into motion, the load swings, and the entire structure shudders.

This mechanical violence has severe consequences:

- Brake Wear: Brakes are forced to fight the motor’s momentum to stop the load, wearing down pads rapidly.

- Gearbox Stress: The shock load is transmitted directly through the gearbox teeth, leading to pitting and eventual failure.

- Structural Fatigue: Repetitive impact loads create micro-fractures in the girder welds and end trucks.

While a Gantry Crane operating outdoors might tolerate rougher handling due to its robust A-frame structure, a precision indoor bridge crane requires a smoother touch to maintain its structural integrity over a 20-year lifespan.

How VFD Technology Redefines Lifting

A Variable Frequency Drive (VFD) controls an AC motor by varying the frequency and voltage of the power supplied to it. Instead of the “all-or-nothing” approach of contactors, a VFD ramps the motor up to speed smoothly and ramps it down just as gently.

1. The “Soft Start” Revolution

When a VFD-controlled crane starts, it delivers torque gradually. There is no sudden jerk. The slack in the wire rope is taken up smoothly, and the load lifts without swinging. This “soft start” eliminates the mechanical shock that snaps shafts and couplings. By removing this stress, you effectively double the lifespan of your rotating mechanical components.

2. Regenerative Braking

Perhaps the most significant maintenance advantage of a VFD is how it handles stopping. In a traditional system, the mechanical brake is responsible for stopping the motor. It is a friction device that wears out every time it is used.

With a VFD, the drive slows the motor electrically by reducing the frequency. The motor acts as a generator, slowing the load down without physical friction. The mechanical brake is only engaged after the motor has come to a near-complete stop, essentially acting as a parking brake rather than a service brake. This can extend the life of brake pads by up to 500%, turning a quarterly maintenance task into an annual one.

Precision Positioning and Safety

Beyond maintenance, VFDs offer operational advantages that directly impact productivity.

Micro-Speed and Infinite Control

Traditional 2-speed controls force operators to “jog” or “inch” the crane—rapidly tapping the button to get the load into the exact position. This pulsing sends dozens of shockwaves through the system in seconds.

VFDs allow for infinite variable speed control. An operator can move a 20-ton die at a crawling speed of 0.5 meters per minute for final placement, then accelerate to 40 meters per minute for the return trip. This precision eliminates the need for jogging, further reducing wear on contactors and motors.

Sway Control

Advanced VFD systems include anti-sway algorithms. By mathematically predicting the pendulum effect of the load based on the trolley’s acceleration, the drive adjusts the motor speed to counteract the swing. This keeps the load stable, protecting ground personnel and preventing collisions with racking or other machinery. This feature is particularly valuable when moving large, unwieldy loads that are typical for a heavy-duty Gantry Crane in shipping yards or steel depots.

The Impact on Total Cost of Ownership (TCO)

Procurement teams often balk at the upfront cost of VFD systems, which can be 15-20% higher than contactor-based equivalents. However, when viewed through the lens of TCO over a 10-year period, the VFD is significantly cheaper.

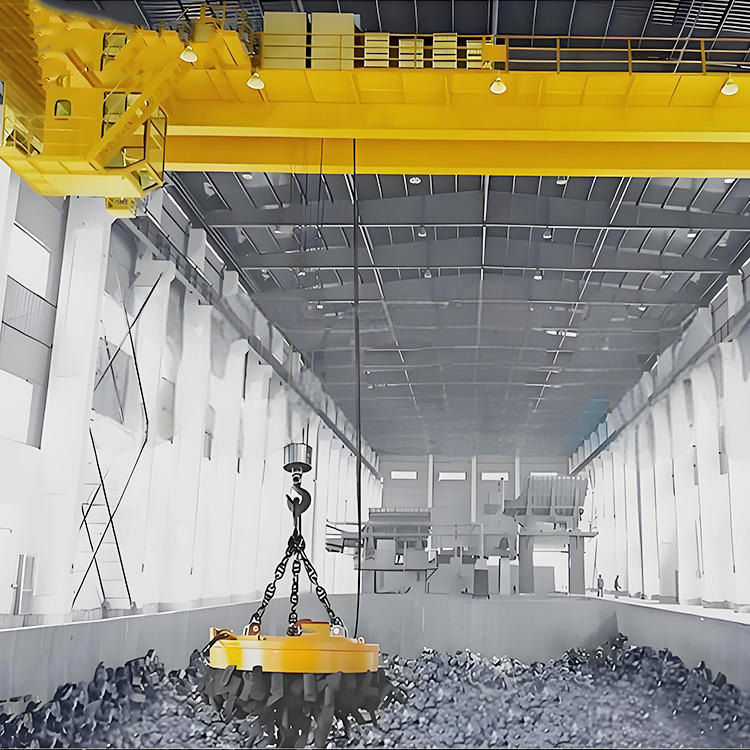

Weiyuan QD Type Overhead Crane for Steel Mills – Heavy Duty & Heat-Resistant

The Weiyuan QD Type Overhead Crane is engineered for demanding steel mill environments, offering heavy-duty load handling, enhanced heat-resistant components, and rugged performance. Designed for continuous operation under elevated temperatures, this crane delivers reliable material handling for intense industrial applications. ([chengduweiyuan.com](https://chengduweiyuan.com/cranes/bridge-crane/weiyuan-weiyuan-qd-type-overhead-crane-for-steel-mills-heavy-duty-heat-resistant-high-performance/))

View Product / Get QuoteEnergy Efficiency

VFDs optimize the power consumption of the motor. Unlike contactors that draw massive in-rush currents during starting, VFDs ramp up current linearly. Additionally, during deceleration, regenerative units can feed energy back into the facility’s grid, lowering the overall electricity bill.

Reduced Component Replacement

Let’s analyze the replacement cycle for a standard heavy-duty cycle crane:

| Component | Traditional Cycle | VFD Cycle | Savings Factor |

|---|---|---|---|

| Brake Discs | Every 3-6 months | Every 18-24 months | 4x – 6x |

| Contactors | Every 1-2 years | Every 5-8 years | 4x |

| Wire Rope | Every 2 years | Every 3-4 years | 1.5x – 2x |

| Gearbox Oil | Every 6 months | Every 12 months | 2x |

The labor cost alone of replacing brake discs four times a year far outweighs the initial premium of the VFD drive.

Diagnostic Intelligence: Predictive Maintenance

Modern VFDs are not just power supplies; they are computers. They constantly monitor motor current, voltage, temperature, and torque. This data stream unlocks the potential for predictive maintenance (PdM).

Instead of waiting for a failure, maintenance teams can monitor the VFD’s fault codes and performance logs.

- Current Spikes: If the drive detects a gradual increase in current draw over a month, it might indicate a failing bearing or a lack of lubrication in the gearbox long before the component seizes.

- Load Spectrum Recording: The VFD can track the “Safe Working Period” (SWP) by logging exactly how much weight the crane has lifted and how often. This allows managers to schedule major overhauls based on actual usage rather than arbitrary calendar dates.

This level of intelligence is becoming standard in complex lifting equipment, from the humble workshop jib to the massive ship-to-shore Gantry Crane found in ports.

Retrofitting: Breathing New Life into Old Iron

For facilities with existing cranes that are mechanically sound but electrically outdated, a VFD retrofit is a highly cost-effective strategy.

Replacing the entire crane is expensive and disruptive. By stripping out the old contactor panel and installing a modern VFD control cabinet, you can essentially upgrade a 1990s crane to 2026 standards. This retrofit usually includes replacing the festoon system and pendant, ensuring the electrical backbone is robust enough to handle the new drives.

Key Considerations for Retrofitting

- Motor Compatibility: Ensure your existing motors are “inverter duty” rated. Older motors may have insulation that cannot handle the voltage spikes associated with VFDs.

- Cooling: VFD motors can run slower for longer periods. Standard fans attached to the motor shaft might not provide enough cooling at low speeds, necessitating forced cooling fans.

- Resistors: Dynamic braking requires braking resistors to dissipate the energy generated by the motor during stopping. These need to be properly sized and mounted to handle the heat.

Selecting the Right Drive for Your Application

Not all VFDs are created equal. For overhead lifting, general-purpose “pump and fan” drives are insufficient. You require drives specifically engineered for hoisting applications.

Closed-Loop vs. Open-Loop

- Open-Loop Vector Control: Suitable for most traverse motions (trolley and bridge travel). It provides excellent speed control without needing feedback from the motor.

- Closed-Loop Flux Vector Control: Essential for the hoist motion (lifting). This system uses an encoder on the motor shaft to provide feedback to the drive. This ensures the drive knows exactly where the load is and can hold it at zero speed (hovering) without the brake engaging. This is critical for safety, preventing “load droop” when the brake releases.

The Future of Connected Lifting

The integration of VFDs is the first step toward the Industrial Internet of Things (IIoT). Modern drives can communicate via Ethernet or Wi-Fi to a central plant control system.

Imagine a scenario where your maintenance manager receives a text message: “Crane #4 Hoist Brake Air Gap approaching limit. Schedule adjustment.” This isn’t science fiction; it is the current capability of high-end VFD systems.

For large-scale operations utilizing a Gantry Crane fleet, this connectivity allows for centralized monitoring of asset health across a sprawling site, ensuring that no machine is left unmonitored.

Frequently Asked Questions (FAQ)

Q: Can I install a VFD on any existing overhead crane?

A: In most cases, yes. However, the motors must be evaluated. If the motors are very old (pre-1990s), their insulation might not withstand the Pulse Width Modulation (PWM) of a VFD. In such cases, the motors might need to be replaced or rewound with inverter-grade insulation.

Q: Does a VFD reduce the lifting capacity of my crane?

A: No. A VFD provides full torque throughout the speed range. In fact, some VFDs offer “extended speed” ranges, allowing the hook to move faster than rated speed when it is empty or lightly loaded, actually increasing productivity.

Q: Why do I still need a mechanical brake if the VFD stops the load?

A: The mechanical brake is a critical safety redundancy. It is required by code (such as OSHA and CMAA) to hold the load when the power is off or in the event of a drive failure. The VFD does the “heavy lifting” of stopping the motion, but the mechanical brake holds it in place.

Q: Is VFD control suitable for outdoor cranes?

A: Absolutely. Outdoor cranes, such as a Gantry Crane, benefit immensely from VFDs. The soft start/stop helps maintain traction on wet or icy rails, preventing wheel slip and reducing wear on the drive wheels and tracks. Ensure the control panel enclosure is rated NEMA 4/IP65 for weather protection.

Q: What is the ROI timeline for a VFD retrofit?

A: Depending on the duty cycle of the crane, the Return on Investment is typically seen within 18 to 24 months. This calculation includes energy savings, reduced replacement part costs (brakes, contactors), and the avoided cost of production downtime.