Universal electric hoist

Custom Fabricated Steel Structures Electric Hoist

Product Overview

Weiyuan provides high-quality, custom-fabricated steel structures engineered to meet the precise specifications of your most demanding projects. As a leading manufacturer with decades of experience, we specialize in transforming raw steel into bespoke components for crane systems, industrial buildings, equipment frames, and complex architectural designs. Our advanced manufacturing facility, combined with a team of expert engineers and certified welders, allows us to deliver superior-quality steel products that are strong, precise, and built to last. From simple weldments to large, intricate assemblies, we are your trusted partner for all custom steel fabrication needs.

Product Advantages

Precision Engineering and Manufacturing

Our process begins with detailed engineering and design using advanced CAD/CAM software. This ensures every cut, bend, and weld meets your exact tolerances. We employ state-of-the-art manufacturing techniques, including CNC cutting and robotic welding, to guarantee exceptional accuracy and consistency across all fabricated parts.

High-Quality Materials and Certification

We source only high-grade, certified steel (such as Q235B, Q345B, and other international standards) from reputable mills. All materials come with full traceability and certification, ensuring the structural integrity and reliability of the final product. Our commitment to quality materials means your structure will perform as expected under its intended loads.

Comprehensive Fabrication Capabilities

Weiyuan is a one-stop shop for all your steel fabrication needs. Our capabilities include heavy plate cutting, forming, advanced welding (MIG, TIG, SAW), precision machining, sandblasting, and industrial-grade painting. This integrated approach simplifies your supply chain and ensures a seamless transition from design to finished product.

Certified Welding and Quality Assurance

Our welders are certified to international standards, and all welding procedures are rigorously controlled. We conduct comprehensive quality checks, including non-destructive testing (NDT) such as ultrasonic and magnetic particle inspection, to verify weld integrity and ensure your components are free from defects.

Cost-Effective and Timely Delivery

Leveraging nearly 40 years of manufacturing experience and an efficient production process, we deliver custom steel structures at a competitive price point without compromising on quality. Our project management team ensures your order is completed on schedule, helping you avoid costly project delays.

Application Scenarios

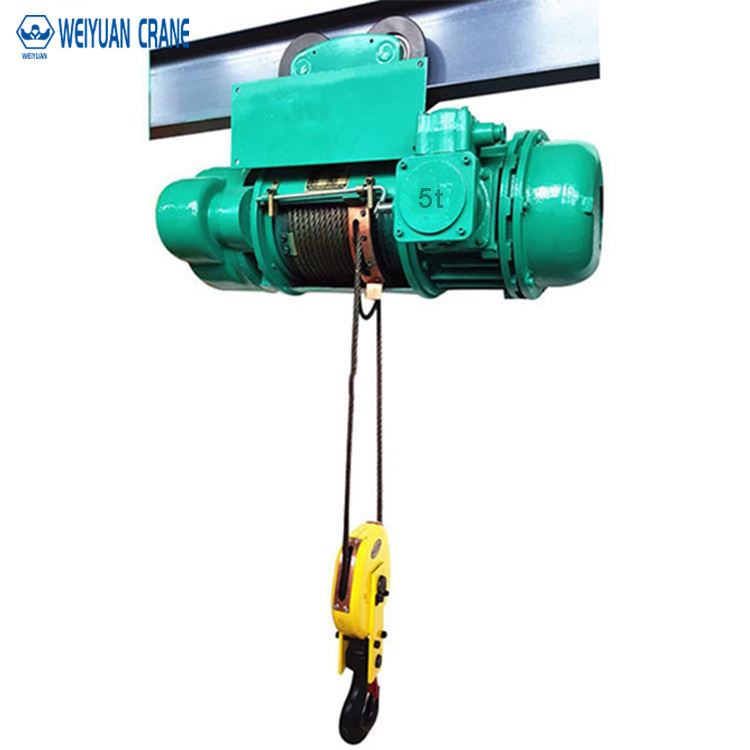

Crane and Hoist Manufacturing

We are experts in fabricating the core structural components for overhead cranes, gantry cranes, and jib cranes. This includes main girders, end carriages, support legs, and trolley frames, all engineered to handle heavy loads safely.

Industrial Buildings and Structures

We provide the steel backbone for warehouses, workshops, and manufacturing plants. Our products include support columns, roof trusses, runway beams, and mezzanines, all fabricated to support your operational infrastructure.

Heavy Equipment and Machinery Frames

Our custom steel fabrications serve as the robust chassis and support frames for heavy industrial machinery, construction equipment, and specialized manufacturing systems, providing the strength and rigidity needed for demanding applications.

Architectural and Construction Projects

We collaborate with contractors and architects to create custom structural and architectural steel for buildings, bridges, and unique public works projects, turning complex designs into reality.

Product Specifications and Dimensions

| Specification | Parameters |

|---|---|

| Material Type | Carbon Steel (Q235B, Q345B), High-Strength Steel, Stainless Steel, or per client specs |

| Fabrication Capacity | Up to 500 tons per single component; 60,000+ tons annually |

| Max. Component Size | Length up to 50m, Width up to 10m (subject to transport limitations) |

| Welding Standards | AWS, ISO, EN, or equivalent |

| Surface Treatment | Sandblasting (Sa2.5), Primer, Epoxy Paint, Polyurethane Top Coat, Hot-Dip Galvanizing |

| Quality Control | Material Certification, Dimensional Inspection, Non-Destructive Testing (NDT) |

| Design Software | AutoCAD, SolidWorks, Tekla Structures |

| Plate Thickness | 6mm – 200mm |

| Machining Tolerance | Up to ±0.01mm for critical surfaces |

| Main Fabrication Processes | CNC Plasma/Laser Cutting, Bending, Rolling, Welding, Machining, Assembly |

| Applicable Industries | Heavy Lifting, Construction, Manufacturing, Energy, Shipbuilding, Mining |

Features at a Glance

✓ Fully Custom Design: Engineered and fabricated to your exact project drawings and specifications.

✓ Certified Materials: Use of high-grade steel with full traceability and certification.

✓ Advanced Welding: Certified welders and processes ensure superior structural integrity.

✓ Precision Manufacturing: CNC cutting and machining for tight tolerances and accuracy.

✓ Comprehensive Quality Control: Includes NDT to guarantee defect-free components.

✓ Industrial-Grade Finishing: Multi-layer painting or galvanizing for long-term corrosion protection.

✓ One-Stop Solution: From design and fabrication to finishing and assembly.

FAQ

Q: What information do I need to provide to get a quotation for custom steel fabrication?

A: To provide an accurate quote, we need detailed engineering drawings (in .dwg or .stp format), material specifications (e.g., Q345B steel), required quantity, surface treatment requirements (e.g., painting system), and any specific testing or inspection standards you require.

Q: Can you handle both large and small fabrication projects?

A: Yes. Our facility is equipped to handle a wide range of projects, from small, precision weldments to massive structural assemblies weighing hundreds of tons. No project is too big or too small.

Q: What is the typical lead time for a custom fabrication order?

A: Lead time depends on the complexity, size, and quantity of the order. A simple project may take a few weeks, while a large, complex fabrication project could take several months. We will provide a detailed production schedule with our quotation.

Q: Do you provide design and engineering services?

A: Our primary service is fabrication based on client-provided designs. However, we have a team of experienced engineers who can review your designs for manufacturability (DFM) and collaborate with your team to optimize the structure for performance and cost-effectiveness.

Q: How does Weiyuan ensure the quality of its fabricated steel structures?

A: With nearly 40 years of manufacturing experience, Weiyuan operates under a strict ISO-certified quality management system. Quality is controlled at every stage: incoming material inspection, in-process dimensional checks, certified welding procedures, comprehensive NDT of all critical welds, and a final inspection of dimensions and paint quality before shipment. We provide a full Quality Control Report with every project.