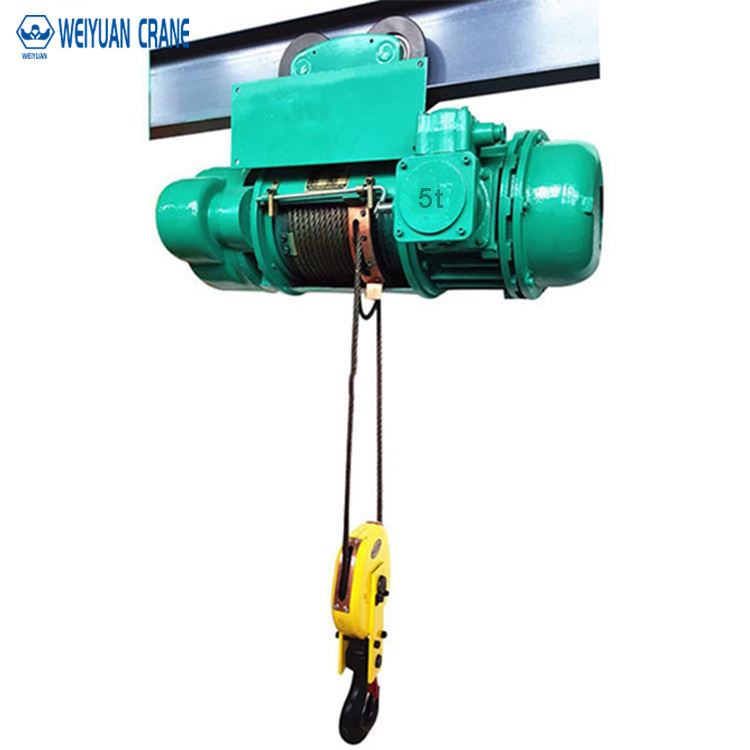

Universal electric hoist

Weiyuan European-Standard Double Girder Hoist

Product Overview

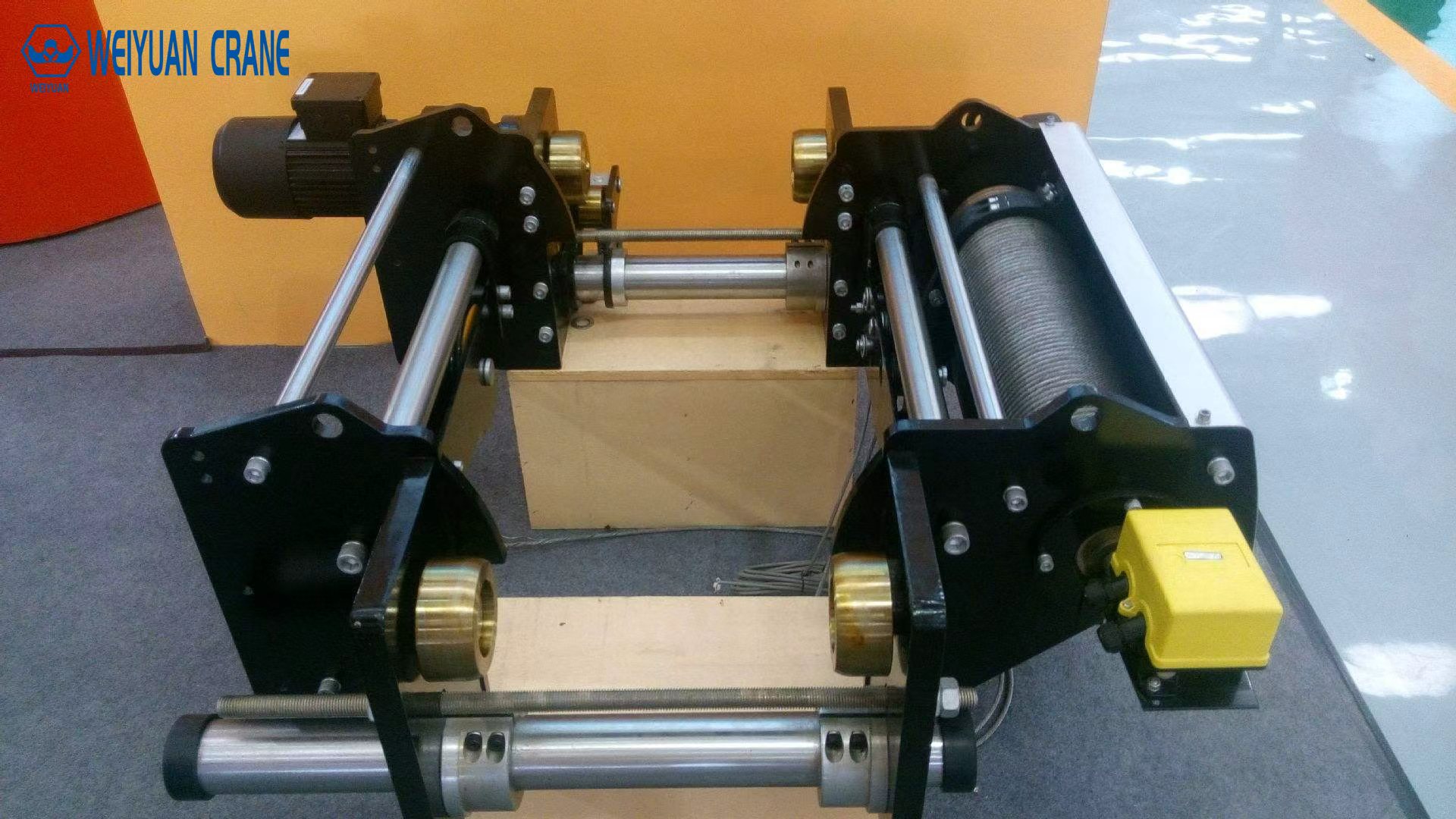

The Weiyuan European-Standard Double Girder Hoist is a high-performance lifting mechanism engineered for heavy-duty applications on double girder overhead and gantry cranes. Designed with advanced European FEM standards, this hoist offers exceptional reliability, efficiency, and a long service life. Its modular construction, featuring a high-quality motor, hardened gearbox, and advanced braking system, ensures precise and stable operation. With customizable capacities and standard VFD controls, this hoist is the premier choice for demanding environments like steel manufacturing, heavy equipment assembly, and large-scale industrial workshops where power and precision are non-negotiable.

Product Advantages

Superior Performance and Precision

Equipped with Variable Frequency Drives (VFD) as standard, this hoist delivers incredibly smooth and precise control over lifting and travel movements. The stepless speed control eliminates load shock, minimizes swing, and allows for exact positioning of heavy and high-value loads, dramatically improving both safety and operational efficiency.

Robust Design for Heavy-Duty Use

Engineered for A5-A6 duty cycles, this hoist is built to withstand the rigors of frequent, heavy use. It features a high-performance motor, a durable hardened-tooth gearbox, and a robust frame, all designed to provide maximum reliability and a long service life in the most demanding industrial environments.

Optimized for Double Girder Cranes

This hoist trolley is specifically designed to run on top of double girder cranes, providing exceptional stability and maximizing the crane’s lifting height. Its open, accessible layout simplifies inspection and maintenance procedures, reducing downtime and ensuring the system remains in peak condition.

Enhanced Safety as Standard

Weiyuan prioritizes safety above all. This hoist comes with a comprehensive suite of safety features, including an adjustable overload protection device, a dual-disc electromagnetic brake for secure load holding, and precise upper and lower travel limit switches. These integrated systems ensure fail-safe operation.

Fully Customizable Solution

Understanding that heavy-duty tasks vary, we offer extensive customization. We can tailor the lifting capacity, lifting height, speeds, and control systems to perfectly match your specific application, ensuring you get a powerful lifting solution that is optimized for your workflow.

Application Scenarios

Steel and Metal Manufacturing

An essential tool in steel mills and foundries for handling heavy steel coils, plates, and fabricated sections. Its robust construction and precise control are perfect for the demanding, high-temperature environment of metal production.

Heavy Equipment Assembly

Provides the powerful and stable lifting required for assembling large machinery, vehicles, and turbines. The smooth VFD control allows for the safe and accurate placement of massive components like engines and chassis.

Power Generation and Utilities

Ideal for maintenance and operational tasks within power plants. It is used for lifting and positioning heavy generators, transformers, and other critical equipment with the utmost safety and precision.

Large-Scale Workshops and Precast Yards

Provides powerful lifting coverage for large workshops, precast concrete yards, and infrastructure projects. It easily handles large molds, concrete beams, and other oversized materials, streamlining production and logistics.

Product Specifications and Dimensions

| Specification | Parameters |

|---|---|

| Lifting Capacity | 3t, 5t, 10t, 16t, 32t, 50t (Customizable) |

| Lifting Height | 6m, 9m, 12m, 18m (Customizable) |

| Hoist Type | European-Standard Double Girder Hoist Trolley |

| Work Level | A5 – A6 (Medium to Heavy Duty) |

| Lifting Speed | Dual Speed with standard VFD control |

| Travel Speed | Stepless VFD Control (e.g., 5-20 m/min) |

| Control Method | Wireless Remote Control / Cabin Control |

| Power Supply | 380V/415V/440V, 50/60Hz, 3-Phase or Customized |

| Motor | High-performance squirrel cage motor, IP55 protection |

| Gearbox | Hardened gear surface for long life and low noise |

| Brake | Maintenance-free electromagnetic disc brake |

Features at a Glance

✓ Advanced European Design: Optimized for high performance and reliability.

✓ Heavy-Duty Capacities: Available up to 50 tons and beyond for major lifts.

✓ Standard VFD Control: Provides smooth, stepless operation on all movements.

✓ A5-A6 Duty Cycle: Built for demanding, high-frequency industrial applications.

✓ Durable, Low-Maintenance Components: Hardened gears and IP55 motors for longevity.

✓ Open and Accessible Structure: Simplifies inspection and maintenance tasks.

✓ Comprehensive Safety Features: Includes overload limiters and reliable braking.

FAQ

Q: What is the primary benefit of this hoist for a double girder crane?

A: This hoist provides superior stability, higher lifting capacity, and better lifting height compared to hoists on single girder cranes. Its robust design is specifically matched to the heavy-duty performance of a double girder system, ensuring maximum safety and efficiency for large-scale lifting.

Q: Is VFD (Variable Frequency Drive) control necessary for a heavy-duty hoist?

A: For heavy-duty applications, VFD control is highly recommended and comes standard on our European models. It protects the load, the crane, and the building structure by eliminating sudden shocks. It also allows for precise positioning, which is critical when handling expensive or hazardous materials.

Q: Can this hoist be retrofitted onto an older double girder crane?

A: Yes, it is possible. We would need to verify the gauge (distance between the trolley rails) on your existing crane, as well as the power supply and control system compatibility. Our engineering team can help assess your crane for a potential upgrade.

Q: What information is needed for an accurate quotation?

A: To configure the perfect hoist, please provide: 1) The required lifting capacity (e.g., 20 tons), 2) The lifting height needed, 3) The gauge of your double girder crane, 4) Your facility’s power supply, and 5) The intended application.

Q: How does Weiyuan ensure the quality of its heavy-duty European hoists?

A: With nearly 40 years of manufacturing excellence, Weiyuan builds every European-standard hoist under a strict, ISO-certified quality system. We utilize advanced design principles, premium components from trusted global brands, and conduct extensive load and performance testing to guarantee each hoist delivers superior safety, reliability, and a long service life.