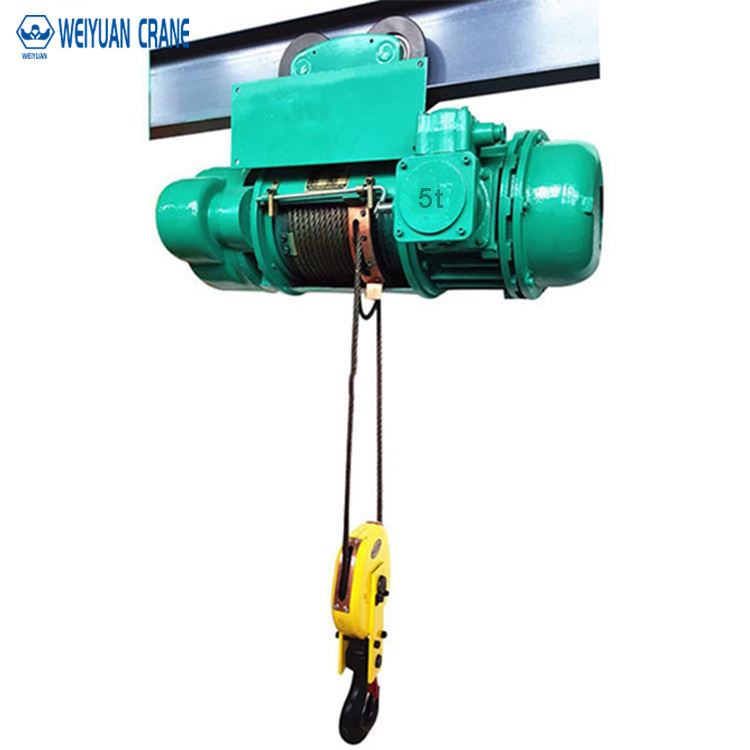

Universal electric hoist

Weiyuan HB Explosion-Proof Electric Hoist

Product Overview

The Weiyuan HB Type Explosion-proof Electric Wire Rope Hoist, available in 3, 5, and 10-ton capacities, is a specialized lifting solution meticulously engineered for safety in hazardous environments. This hoist is indispensable for operations where the atmosphere may contain flammable gases or combustible dust, such as in the chemical, oil & gas, and mining industries. Every component, from the motor to the control box and limit switches, is designed with certified explosion-proof technology to eliminate potential ignition sources. The Weiyuan HB hoist combines this critical safety focus with robust construction and reliable performance, ensuring your team can handle heavy materials with confidence and security in the most demanding conditions.

Product Advantages

Certified for Hazardous Environments

Safety is paramount. The Weiyuan HB hoist is built to strict explosion-proof standards (Exd II BT4 and CT4), featuring fully enclosed motors and electrical components that prevent internal sparks from igniting the surrounding atmosphere. This certification provides the highest level of assurance for safe operation in high-risk zones.

Robust, Heavy-Duty Construction

Engineered for durability, this hoist features a solid steel frame, a high-strength gear train, and a wear-resistant wire rope. This rugged build ensures it can withstand the harsh conditions of industrial use, providing a long service life with exceptional reliability and minimal maintenance.

Flexible and Customizable Performance

Available in popular 3, 5, and 10-ton capacities, the HB hoist can be fully customized to your operational needs. We offer options for lifting height, single or dual-speed control, and specific explosion-proof ratings to create a lifting solution that is perfectly tailored to your application.

Enhanced Safety Features

Beyond its core explosion-proof design, the hoist is equipped with a comprehensive suite of safety mechanisms. These include a reliable conical rotor motor brake for immediate load holding, upper and lower limit switches to prevent hook accidents, and optional spark-resistant components like bronze hooks and wheels for an added layer of protection.

Compact and Versatile Design

The hoist’s compact and logical design allows for easy integration into various crane systems, including single-girder, double-girder, or monorail setups. It provides powerful lifting without requiring excessive space, making it a versatile choice for both new installations and retrofits.

Application Scenarios

Chemical Processing Plants

An essential tool for lifting pumps, mixers, and containers of raw materials in environments where chemical vapors are present. The explosion-proof design is critical for maintaining site safety.

Oil & Gas Refineries

Ideal for maintenance and material handling tasks in refineries and on drilling platforms, where the risk of flammable gases is constant. It ensures the safe movement of valves, pipes, and other heavy equipment.

Ammunition and Explosives Storage

Provides the necessary certified safety for lifting and transporting materials in military depots, munitions factories, and other facilities where extreme caution is required.

Paint and Varnish Production

Safely handles drums of solvents, pigments, and finished products in paint manufacturing facilities where flammable fumes are a part of the daily process.

Product Specifications and Dimensions

| Specification | Parameters |

|---|---|

| Lifting Capacity | 3t, 5t, 10t (Customizable) |

| Lifting Height | 6m, 9m, 12m, 18m, 24m (Customizable) |

| Hoist Type | HB Model Explosion-proof Wire Rope Hoist |

| Work Level | A3 (M3) |

| Explosion-Proof Grade | Exd II BT4 / Exd II CT4 |

| Lifting Speed | Single Speed (e.g., 8m/min) or Dual Speed (e.g., 8/0.8m/min) |

| Travel Speed | 20 m/min (or as required) |

| Control Method | Explosion-proof Pendant Control / Explosion-proof Wireless Remote |

| Power Supply | 380V/415V/440V, 50/60Hz, 3-Phase |

| Motor Protection | IP54 / IP55 |

| Spark-Resistant Features | Optional (Bronze-coated wheels, hook, etc.) |

Features at a Glance

✓ Certified Explosion-Proof: Built to Exd II BT4/CT4 standards for maximum safety.

✓ Popular Mid-Range Capacities: 3, 5, and 10-ton models for versatile use.

✓ Durable and Reliable: Robust construction for a long service life in harsh conditions.

✓ Customizable Solution: Tailor the capacity, height, and speed to your specific needs.

✓ Comprehensive Safety Systems: Includes reliable braking and travel limiters.

✓ Optional Dual Speed: Provides both fast lifting and precise positioning.

✓ Spark-Resistant Options: Available for environments requiring an extra level of safety.

FAQ

Q: What is the difference between an explosion-proof hoist and a standard hoist?

A: An explosion-proof hoist is specifically designed to operate safely in hazardous environments. Its motors, electrical enclosures, and switches are sealed to prevent any internal sparks from igniting flammable gases or dust in the air. A standard hoist does not have these critical safety protections.

Q: How do I know which explosion-proof grade (BT4 or CT4) I need?

A: The required grade depends on the specific flammable substances present at your facility. The BT4 grade is suitable for most common industrial gases, while the CT4 grade is for highly volatile gases like acetylene and hydrogen. You should consult your site’s safety regulations or contact our experts for guidance.

Q: What information should I provide to get a quote for a 5-ton explosion-proof hoist?

A: To provide an accurate quote, please inform us of: 1) The 5-ton capacity requirement, 2) The necessary lifting height, 3) The explosion-proof grade you need (e.g., Exd II BT4), 4) Your facility’s power supply, and 5) a brief description of the application.

Q: Is maintenance for an explosion-proof hoist more complex?

A: Maintenance is similar to a standard hoist but requires extra diligence. It’s crucial to regularly inspect the seals and flameproof surfaces of all electrical enclosures to ensure their integrity is not compromised. This guarantees the hoist remains compliant and safe.

Q: How does Weiyuan guarantee the quality and safety of its explosion-proof hoists?

A: With nearly 40 years of manufacturing excellence, Weiyuan builds every HB hoist under a strict, ISO-certified quality management system. We use only certified explosion-proof components from trusted suppliers. Each hoist undergoes rigorous load testing and a detailed safety inspection to ensure it fully complies with international standards for operating in hazardous locations.